Aluminum Honeycomb Panel

Manufacturing process

Aluminum honeycomb panel products are made of uniform standard pre-rolled high-grade aluminum alloy coils, combined with a variety of production processes.

Coating technology

1. Adopt original coating baking technology to ensure the adhesion of the coating as well as the uniformity and saturation of the color.

2. The required colors can be provided according to requirements, and various special coatings can also be provided.

Forming technology

1. Through a series of molds, the stress inside the plate is fully released.

2. Protect the coating on the surface of the panel from damage and make it more durable.

3. The entire production process ensures high precision of the plate processing size.

4. The continuous hot composite production process is efficient and fast.

Honeycomb composite technology

1. Derived from the scientific and technological achievements of modern aviation, it is lighter in weight but has higher strength.

2. Use high-temperature composite and panel hot pressing technology to ensure the integrity, strength and flatness of the plate.

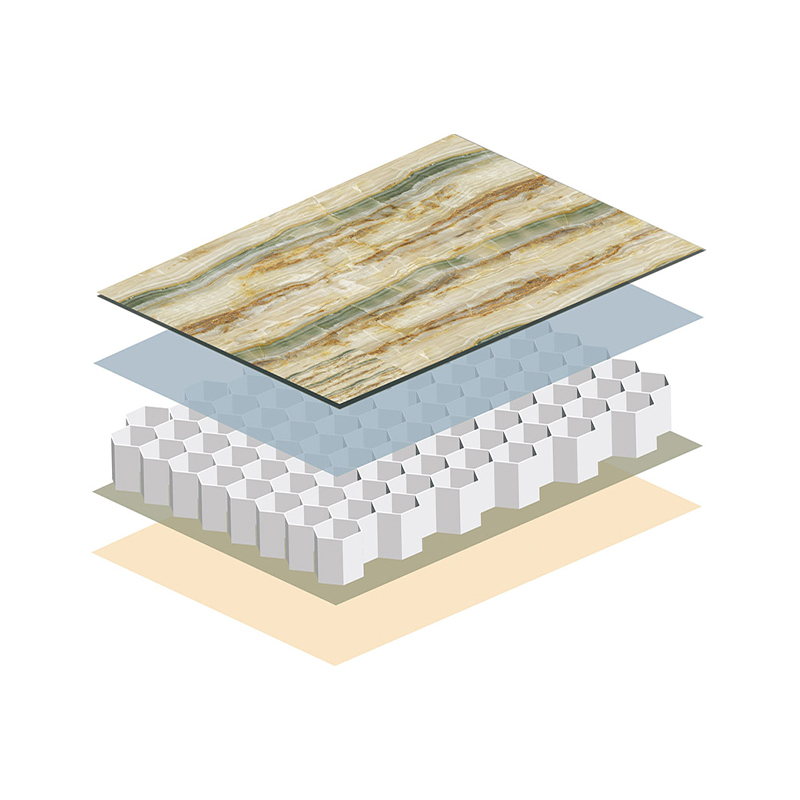

Product structure

Aluminum honeycomb panels use high-strength 3003 aluminum alloy as panels,

high-density aluminum honeycomb as core material, the conventional thickness of the panels is 0.8mm, 1.0mm,

the overall thickness of the panels is 10mm, 5mm, 25mm.

Other specifications, structures and sizes can be designed and manufactured as needed to meet the needs of various uses.

1. Low density: The aluminum honeycomb core structure is a porous discontinuous material, and the cross-section of the solid part is very small, so the density of the nest is very small.

2. Sound insulation and heat insulation performance: After the aluminum honeycomb core is compounded with the aluminum surface bottom plate, the air inside its space is in a sealed state between the aluminum plate and the honeycomb structure, and the air flow is blocked inside the space. The propagation of heat and sound waves is greatly restricted, so the aluminum honeycomb panel has good sound insulation and heat insulation performance.

3. Strong shock absorption performance: The aluminum honeycomb core is a component of the aluminum honeycomb panel. The hexagonal structure restrains each other, like an I-beam, which can disperse and bear pressure from all sides.

4. Superior flatness and rigidity: The honeycomb core is in a vertical stress state. Each panel has countless fixed honeycombs and will not move, ensuring that the panel remains very flat when subjected to pressure and impact.

5. Lightweight and energy-saving: The weight of a honeycomb panel with the same rigidity is only 1/5 of that of an aluminum plate and 1/10 of that of a steel plate. Its cost performance is significantly higher than that of aluminum-plastic panels and aluminum veneers, effectively saving materials.

6. Fire prevention: According to the inspection of the National Building Materials Quality Supervision and Inspection Center, all performance indicators of this material meet the requirements of flame retardant materials.

| ASTM | Unit | 10mm | 15mm | 20mm |

Unit theoretical weight | | kg/m² | 5.4 | 5.6 | 5.75 |

Tensile strength | E8 | N/mm² | 806 | 598 | 455 |

Endurance | E8 | N/mm² | 531 | 405 | 279 |

Elongation | E8 | % | 1.2 | 1.4 | 1.7 |

Bending rigidity | C393 | x10⁶N.mm² | 8.03 | 15.4 | 38.44 |

Bending elastic modulus | | N/mm² | 50000 | 40600 | 38.44 |

Temperature elongation coefficient | D696 | x10⁵N/C | 0.24 | 0.24 | 0.24 |

Thermal conductivity | D976 | kcal/mhr/℃ | 0.23 | 0.19 | 0.15 |

Heat Deflection Temperature | D648 | ℃ | 200 | 200 | 200 |

Bond Strength | C297 | N/mm² | 12 | 12 | 12 |

Board surface flatness | The maximum deviation is 1mm/M |

Flame retardant properties | Non-flammable, in compliance with relevant fire protection standards |

Sound insulation performance | Depending on the panel installation angle, there is 0-3dB |