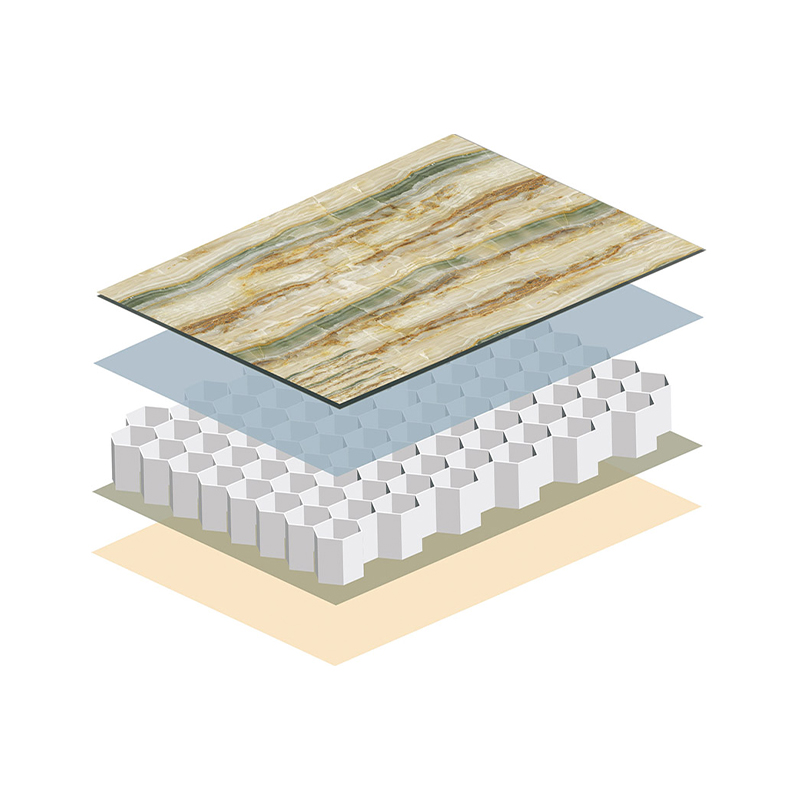

Dragnet aluminum panel, with its open and transparent visual effect, is breaking spatial constraints with a light, dynamic, and modern approach, injecting a sense of breath and artistic tension into public buildings.

- +86-18666360230+86-13594347785

- 334926298@qq.com

- Workshop No. 13, Self compiled, No. 7 Hegui Avenue, Hegui Industrial Park, Zone A, Lishui Town, Nanhai District, Foshan City